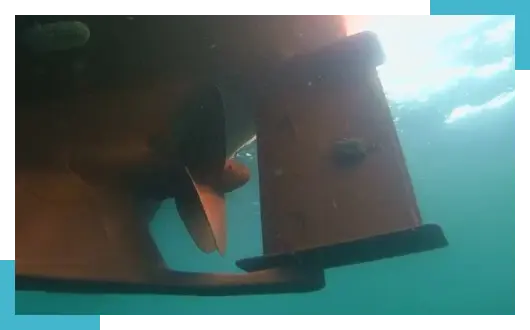

The rudder is an essential component of any ship’s steering mechanism. It helps in directing the vessel in the desired direction and plays a crucial role in ensuring the safety of the ship, crew, and cargo.

However, rudder damage can lead to catastrophic accidents, resulting in significant financial losses, environmental damage, and loss of life. Therefore, it is essential to detect any damage to the rudder early and repair it promptly to prevent any mishap.

In this blog, we will discuss the importance of underwater rudder maintenance, types of rudder damage, causes of damage, early detection methods, and underwater rudder repair, all tailored to the needs of vessels serviced by marine services in the UAE, without necessitating dry-docking.

Types of Rudder Damage:

Rudder damage can occur due to various reasons, such as cracks, corrosion, erosion, and fatigue. Cracks in the rudder can lead to structural failure, causing the vessel to lose control. Corrosion and erosion can weaken the rudder’s metal structure, reducing its ability to withstand pressure and impact. Fatigue damage can occur due to repeated stress on the rudder, causing it to weaken and eventually fail.

Causes of Rudder Damage:

Several factors can cause rudder damage, such as improper maintenance, harsh environmental conditions, collision or grounding. Improper maintenance, such as a lack of lubrication or cleaning, can cause the rudder to corrode and weaken over time. Harsh environmental conditions, such as saltwater exposure and extreme temperatures, can also cause corrosion and erosion. Collision or grounding can lead to cracks and structural damage to the rudder.

Contact Nereus Subsea for the best underwater services Singapore.

Early Detection Methods and Repair Options:

Early detection of rudder damage is crucial to prevent any mishap. The following are some of the methods used to detect rudder damage:

Visual inspection: Regular visual inspection of the rudder can help detect any visible damage, such as cracks or corrosion.

Ultrasonic testing: Ultrasonic testing is a non-destructive testing method that uses sound waves to detect any damage to the rudder.

Magnetic particle inspection: Magnetic particle inspection is another non-destructive testing method that uses magnetic particles to detect any cracks or defects in the rudder.

Once the damage is detected, it is essential to repair it promptly to prevent any further damage or failure. The repair options depend on the type and extent of the damage. Minor damage, such as corrosion or erosion, can be repaired by grinding, sandblasting, and painting.

However, major damage, such as cracks or structural failure, may require a complete rudder repair or replacement. Underwater ship repair and underwater rudder repair services are available to repair or replace the rudder without dry-docking the ship.

Importance of Regular Maintenance and Inspection:

Regular underwater rudder maintenance and inspection are essential to prevent rudder damage in the first place. Proper lubrication and cleaning can prevent corrosion and erosion, while regular inspections can detect any damage early. Underwater maintenance and inspection services can be used to maintain the rudder and detect any damage before it becomes severe.

As the rudder is an essential component of any ship’s steering mechanism, any damage to it can lead to catastrophic accidents. Therefore, it is crucial to detect any damage to the rudder early and repair it promptly to prevent any mishap.

Underwater ship repair and underwater rudder repair services are available to repair or replace the rudder without dry-docking the ship.

The services offered by Nereus for underwater rudder repair involve repairing any damage or wear to the blade of the rudder. The rudder stock is part of the rudder that connects it to the steering system.

Nereus also provides services to repair any damage to the flap, and can also remove or install new flaps as needed. In some cases, it may also be necessary to isolate the flap to prevent damage from galvanic corrosion.

Permanent Weld repairs to erosion or galvanic corrosion damage involve using welding techniques to repair any erosion or galvanic corrosion damage to the rudder. These repairs are designed to be permanent and can help to extend the life of the rudder.

Nereus Subsea delivers a broad range of underwater hull cleaning services across the world, specializing in underwater ship surveys & inspections, underwater maintenance & repair, salvage & recovery and other specialist services to a large and diversified client base.