Underwater ship blanking is a crucial task that is often performed during underwater maintenance, underwater repairs, or emergency situations which is fraught with complexities and potential hazards. This is why vessel owners and operators must make critical decisions when selecting underwater service providers in UAE with safety being paramount.

This blog emphasizes the crucial importance of choosing reliable and high-quality underwater service providers over cost-cutting alternatives and explores the potential hazards associated with underwater ship blanking and the methods to identify and mitigate these risks effectively.

The Importance Of Ensuring Safety in Underwater Diving Operations

Recent accidents within the maritime industry have served as poignant reminders of the severe repercussions that arise from neglecting essential safety protocols. These unfortunate incidents not only jeopardize the safety of divers but can also result in vessels being detained in anchorage for protracted investigations, leading to substantial financial losses and enduring damage to reputation These incidents serve as a stark reminder that precision and diligence must be matched with an unwavering commitment to the well-being of divers. Safety remains the linchpin of successful underwater ship blanking, ensuring that operations run smoothly while safeguarding lives and assets.

Understanding Underwater Ship Blanking

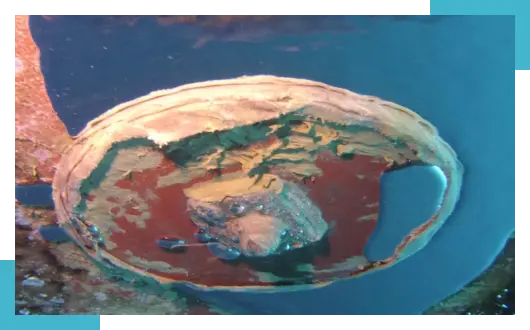

Underwater ship blanking or underwater plugging, is a meticulous process in which specific openings, such as sea chests, valves, or pipes, on a ship’s hull need to be temporarily sealed or blanked off.

This operation becomes indispensable during dry-docking, hull inspections, or critical situations like damage control. The challenge lies in executing these tasks beneath the water’s surface, necessitating the involvement of skilled divers or remotely operated vehicles (ROVs).

Potential Hazards in Underwater Ship Blanking

- Diver Health and Safety:

Foremost among the concerns in underwater ship blanking is the safety and well-being of the divers who carry out these critical tasks. Hazards such as strong underwater currents, reduced visibility, and the risk of entanglement in the ship’s equipment, all of which can pose serious threats to diver safety

- Equipment Failure:

The reliability of the equipment used in the blanking process, including seals and plugs, is paramount. Any equipment failure could result in water ingress and compromise the overall safety of the operation.

- Environmental Impact

Accidental leaks during blanking have the potential to lead to the discharge of pollutants into the water, thus posing significant environmental risks.

- Structural Integrity

Inadequate blanking or improper sealing can impact the ship’s structural integrity, potentially leading to further damage.

Identifying Risks: The Foundation of Safety

Effective risk assessment is the foundation of safe underwater ship blanking. Here are some steps to identify potential hazards:

- Comprehensive Site Survey

Prior to initiating the blanking process, conduct an exhaustive survey of the underwater site. This survey should encompass assessments of underwater conditions, including currents, visibility, and the presence of any potential obstructions.

- Equipment Inspection

Ensure that all blanking equipment, from seals and plugs to specialized tools, is in optimal condition and adheres to stringent safety standards.

- Diver Training and Certification

Divers engaged in underwater blanking operations must be rigorously trained, experienced, and certified. Regular training and drills are vital to maintaining their competency and readiness.

- Environmental Considerations

Evaluate the environmental impact of the blanking operation and formulate measures to prevent and contain any potential spills or discharges.

Mitigating Risks: From Identification to Action

Once potential hazards are identified, it’s crucial to implement risk mitigation strategies:

- Robotic Technology

Nereus Subsea integrates Remotely Operated Vehicles (ROVs) to enhance safety and operational efficiency minimizing the need for divers to engage in dangerous activities like underwater blanking operations. ROVs significantly reduce risks to human life during hazardous underwater tasks

- Emergency Response Plan

Nereus Subsea’s dedication to safety is reflected in its comprehensive emergency response systems. Diving vessels are strategically equipped to facilitate simultaneous dives, and robust communication systems ensure swift responses to distress signals. This level of preparedness minimizes the potential impact of unforeseen circumstances.

- Quality Assurance

Nereus enforces strict quality control measures to ensure the integrity of blanking equipment and the effectiveness of the sealing process. This involves rigorous testing and verification.

- Environmental Safeguards

By installing effective containment systems to capture any potential discharges and having oil spill response equipment readily available, Nereus swiftly and effectively manages environmental incidents.

Safety at the Forefront

Underwater ship blanking is a critical operation that demands meticulous risk assessment and mitigation efforts that are non-negotiable. By identifying potential hazards and proactively implementing effective safety measures, the maritime industry can ensure the health and safety of divers, safeguard the environment, and maintain the structural integrity of vessels. Safety should always be the top priority when undertaking such complex underwater tasks.

At Nereus, the best ship repair company in Singapore, we are committed to playing a pivotal role in ensuring the safety, efficiency, and environmental responsibility of underwater ship blanking operations.

Our cutting-edge technologies, including advanced remotely operated vehicles (ROVs) and state-of-the-art equipment, are designed with safety as a top priority. We understand that the maritime industry’s success hinges on the ability to carry out critical operations with the utmost precision and security.

Nereus ensures that divers and technicians involved in underwater blanking are well-prepared and highly skilled along with blanking of seachest repairs and underwater plugging services by changing defective valves and repairing sea chests plating, while afloat during normal ship operations.

In every aspect of our services, Nereus strives to set the gold standard for safety in underwater ship repair in the maritime industry. Our dedication to identifying, mitigating, and managing risks in underwater ship blanking not only ensures the protection of assets and the environment but also safeguards the well-being of those who undertake these vital operations.